For All Your Conventional or

Specialty Packaging Needs

Our experienced staff from customer service, manufacturing engineering,

quality assurance to the shipping department are at your

service to deliver the project to your precise specifications.

We’re Here to Assist YOU with

Products…

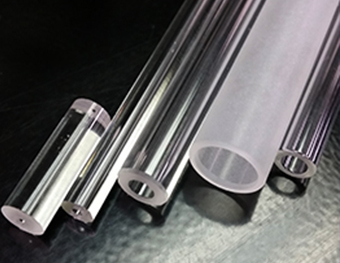

- High Recovery Vials, an alternate packaging option for maximum retrieval of high cost samples or drugs. The vials are available in various volume fill capacities in both amber and type I clear glass, as well as either screw thread or crimp seal finishes.

- Wholesale Glass Vials in clear or amber 6mm to 32mm OD in lengths from 8mm to 178mm with a choice of screw thread or crimp seal neck finish.

- Aluminum seals, lined and unlined

- 13 & 20mm stoppers

- Custom printing and labeling services

- Bulk glass vials, consumable glass packaging, capillary tubes, crimp vials, dropper vials, injection vials, clear glass vials, amber vials, culture tubes, borosilicate glass, flat bottom glass vials, round bottom glass vials, tamper evident glass vials, tubular glass vials, screw thread vials, vaccine vials, wholesale glass vials, V vials, 1mL sampler vials, specialty vials

Process Capabilities…

- Dimensional ranges of 6mm up to 32mm OD and over-all lengths from 10mm up to 178mm to accommodate volume capacities ranging from 50µL’s to 100mL’s – based on vial specifications

- Tooled screw thread and crimp seal neck finishes to meet GPI, ISO and DIN standards

- Machine flexibility designed to support sample development thru high volume commercial production quantities

- Multiple domestic & worldwide sources to facilitate competitive and continuous supply chain for Type I borosilicate clear and amber glass tubing

Service…

- On-site engineering and technical team dedicated to solving your packaging challenges quickly. Specializing in new project development, and sample qualification lots through high volume production requirements

Quality…

- ISO 9001:2015

- 100% of vial production lines equipped with electronic vision gauging for dimensional inspection & rejection.

- Vials packed in environmentally controlled clean rooms for cleanliness of vials when received.

- Drug Master File current with FDA for customer access

- In-house USP and EP Hydrolytic Resistance test certification

A Product of Precision

Scientific & Pharmaceutical

Automotive

Electronic Applications

Medical Applications

Cosmetic Applications

Industrial & Diagnostic

Call Richland Today

856-691-1697

“Richland Glass has been a major supplier of high quality OEM components for our company for over 12 years and has always provided excellent customer service without compromise.” Robert A. – President & CEO - Data Technology

“Richland Glass is one of the few remaining companies which retain the equipment and expertise needed to produce quality glass-to-metal seals and are willing to work with customers who rely on this technology. Richland Glass has been supplying our production line with on time deliveries of critical components for over 15 years.” Jon P – Op to-Mechanical Engineer for a leading government contract OEM manufacturer

Call us today: 856-691-1697 or fill out a form HERE.