Prototyping – Made to Custom Specs

Our experienced staff from customer service, engineering, quality assurance to the shipping department are at your service to deliver the project to your precise specifications. Our dynamic prototyping services deliver production value solutions at the most critical phase of manufacturing, the Beginning.

We’re Here to Assist YOU with

Products…

- Made-to-order glass vials/components to customer approved specifications

Process Capabilities…

- Small to high volume sample capacities

- Single piece thru line trial quantities

- Direct interfacing w/customer to ensure all parts meet expectations

- Responsive turnaround

- Glass shrinking

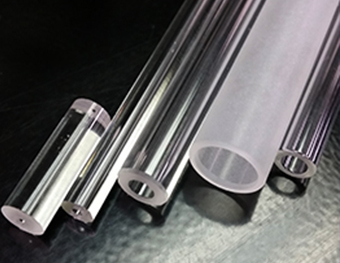

- Precision Glass Tubing

- Crushable Glass Ampoules

Service…

- On-site engineering teams dedicated to providing solutions to customer challenges

- Specializing in custom manufacturing, development and sample qualification lots

Quality…

- ISO 9001:2015 certification

- All parts go through several quality inspections to ensure the customer receives the highest quality product

- Drug Master File current w/ FDA for customer access

- ITAR Registered Manufacturer

Call Richland Today

856-691-1697

A Product of Precision

Scientific & Pharmaceutical

Automotive

Electronic Applications

Medical Applications

Cosmetic Applications

Industrial & Diagnostic

“Richland Glass has been a major supplier of high quality OEM components for our company for over 12 years and has always provided excellent customer service without compromise.” Robert A. – President & CEO - Data Technology

“Richland Glass is one of the few remaining companies which retain the equipment and expertise needed to produce quality glass-to-metal seals and are willing to work with customers who rely on this technology. Richland Glass has been supplying our production line with on time deliveries of critical components for over 15 years.” Jon P – Op to-Mechanical Engineer for a leading government contract OEM manufacturer

Call us today: 856-691-1697 or fill out a form HERE.